Week 5 Update:

Hey everyone, 135 had another productive week of which we are excited to share. These past few days have mostly consisted of testing for failure points from our intake to turret and making changes! It’s all about failing FORWARD to competition.

Intake:

Before, we had the intake powered using the same motor as the roller floor motor, but when we got jams, we would stop intaking. We simply added a motor close to the intake pivot point to independently drive the intake. The additional motor prevents overheating and smoother intake. We have yet to test it out although this new version of our Intake has been mostly mounted.

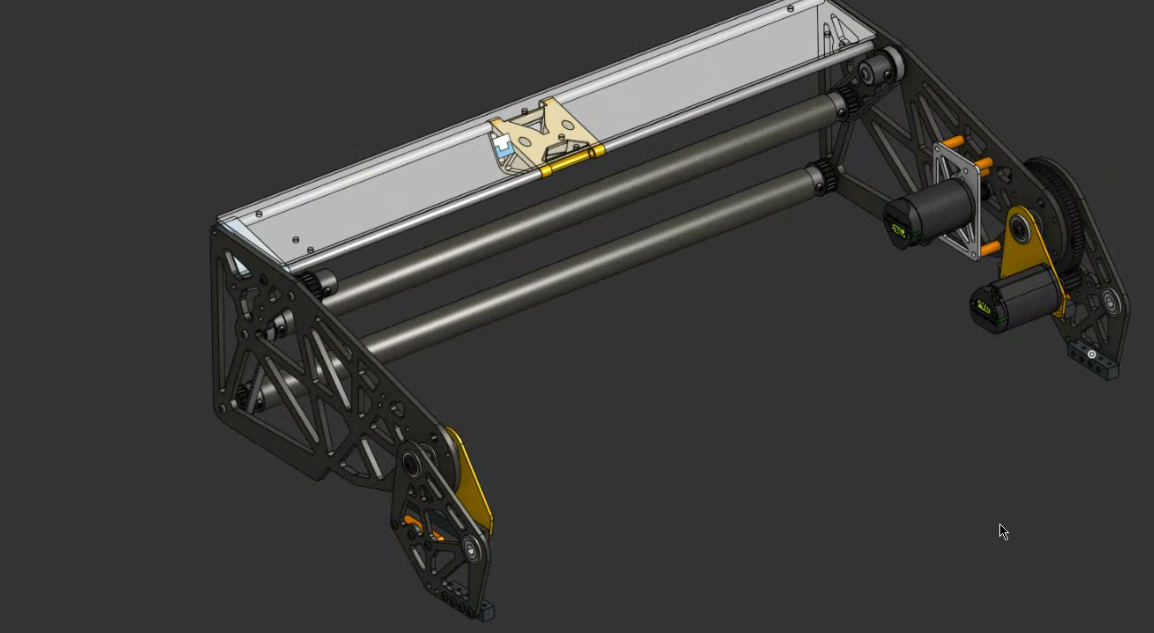

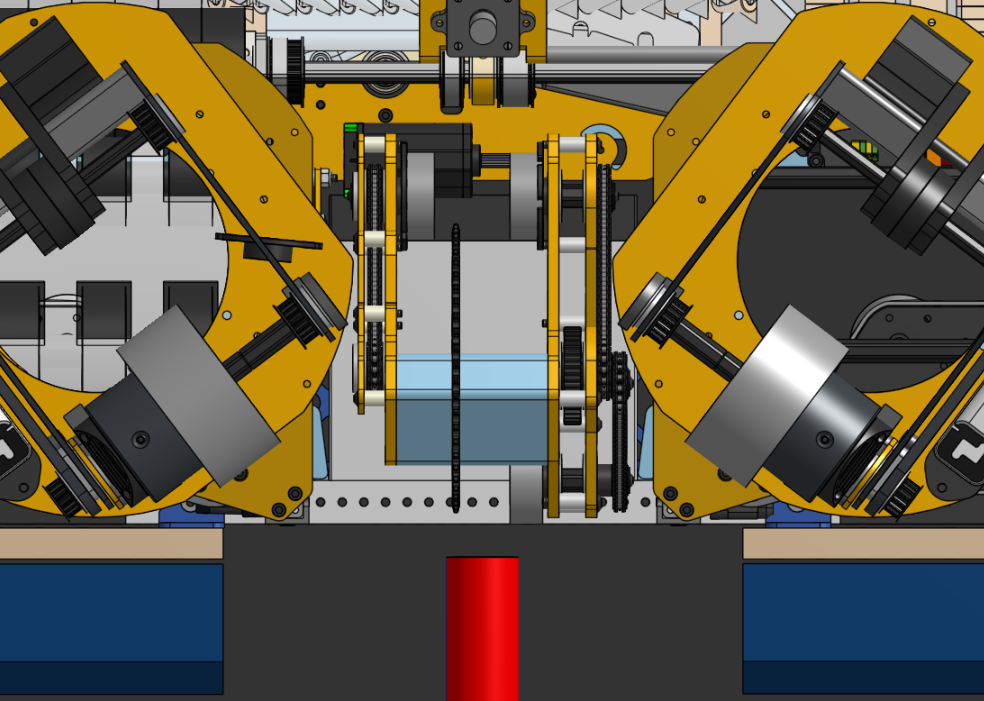

Indexer Iterations:

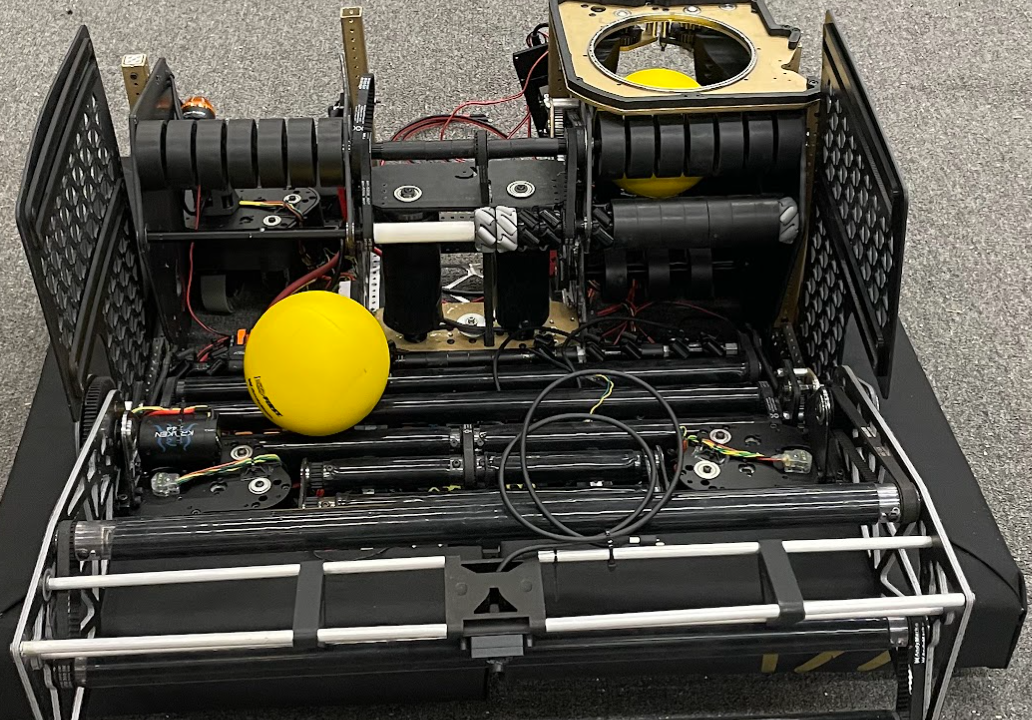

During our first round of indexing tests, we identified several issues with our original V-indexer design. Although the mecanum wheels on the first elevated axle were intended to guide the ball toward the right side, they often caused the ball to wedge against the Lexan plate, resulting in inconsistent feeding and occasional chunking of the foam. Additionally, the V-indexer was not generating the level of forward compression and flow that we had anticipated, which limited our overall cycle consistency. Below is a look at last week’s indexing setup.

At the center of the new design, we implemented an enter splitter to better control initial ball placement. Rather than driving a strict V-index configuration, we transitioned to a passive guide that directs balls toward the turret side, reducing unnecessary lateral force. We also added more 3D printed mecanum wheels to create smoother transfer paths with varying overall diameters. Finally, we refined and smoothed the Lexan edges to eliminate sharp transitions that previously contributed to ball damage and jamming.

We have yet to test this new version of our indexers(since some parts have not been machined), but we will update you all on our observations for this new design next week.

Hang:

Hang is progressing… decently. This next week is going to be a week of getting the geometry 100% correct in V2, building, and testing.

We were so happy when our sprockets and gears arrived. Legend has it that our main hang designer did a literal jump for joy when she was told they’d been delivered to our school…

(designers with their beloved sprockets)

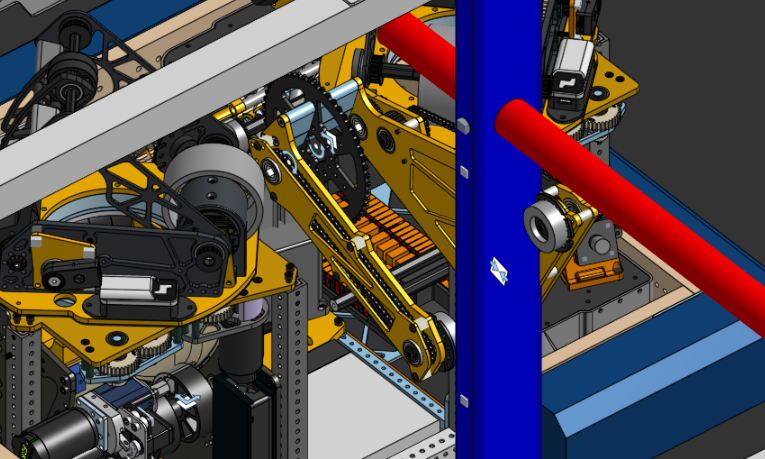

This past week's progress has been enlightening but also very limited. But the upside is that there was a lot learned. Once we had the (majority) of our correct sprockets delivered, it was time to assemble everything that we could, and that started with the THRILLINGLY FUN TASK of doing the internal sprocket system. Having a motor, sprocket, many 3d printed spacers, a shaft adapter, and a #35 chain all in the same tiny axle was not fun. Having to put a big ol #35 chain in there at the same time because if we had put that #35 chain in before everything was screwed in, there would be no way to actually get the screws in! So cue the next hour I spent trying to get the other side of the chain looped around that sprocket and up to the next one.

Here are some tips if you have to do something similar:

- Don’t.

- If you must, get others to help you. Two sets of hands will be really useful.

- Drop chain/belts down, not too far, and try to spin the sprocket/pulley to get it to wrap around. Get gravity to help you–hold it upside down and grab an unwound paper clip to help you fish out that chain. Once you have it through, DON’T LET IT GO.

Then, of course, since the chain was an odd number, we couldn't even put it together because we didn't have any half master links.

So naturally, we tied it off with some scrap CAN wire and moved on to the next thing. Immediately after, I definitely didn't drop a MAXplanetary on the ground and have to reassemble it (I have so much coordination), then we couldn’t find the spline to hex adapter to mount it, so we went to cutting chains. Luckily, all of them were odd, so we couldn’t put any of them together! (Sarcasm detected). Additionally, we couldn’t get our 48 tooth sprockets in time, so we had to order 54 tooth sprockets, which unfortunately didn’t fit because they hit one of the X44s.

Time for a V2.

MONDAY–GEOMETRY DAY!!!!

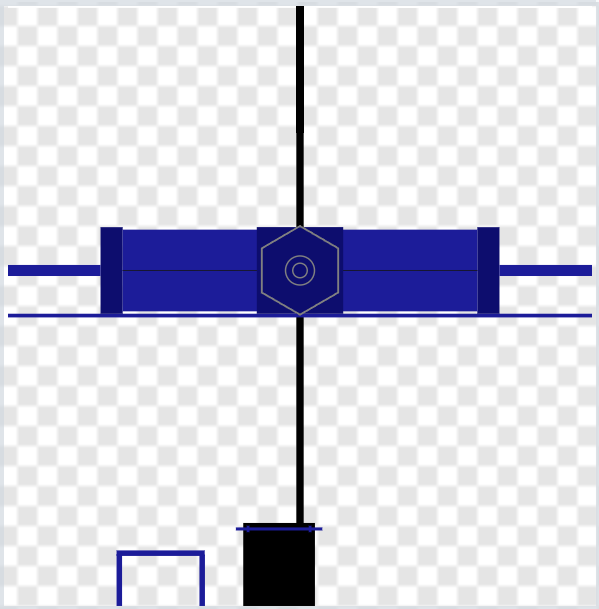

As of the day of posting this, we did a great deal to get our in-CAD geometry correct and to a point where we’re *mostly* confident it can work in real life. So far, we’ve been successful! Our packaging currently allows us to work around the twin turrets, but it certainly is close, and far from easy. All of our end effector geometry is correct, so the last step is to find the space to connect it all to another X44 for the wheel rotation and a 1x2 extrusion or two to fasten it down. The current idea we’re rolling with is to put a nut strip on our V-Splitter top SRPP plate and attach the 1x2 there, since that’s virtually the only space we have available to put it. However, with all of this reconfiguration comes problems with weight. And it’s extremely hard to reduce any weight of the hang–it’s going to have some of the bulkiest plates on the whole robot. We've reduced as much weight as feasibly possible on the hang, so this upcoming week we’re likely going to be spending a lot of time trying to find where we can lose weight on the rest of our robot, as currently we foresee an almost exact 115lbs with turret wiring. With CAD hopefully done and finalized late tonight/early tomorrow for the hang, hopefully we can see a functioning hang by the end of the week.

Wiring:

Our wirers have been working overtime this past week!

After getting permission from our coaches, 5 of our team members brought the bot home to work on wiring. We were able to get all communications working, as well as get the turret wired. Though we've run into a major problem… The wire storage method we came up with doesn't necessarily work; it would tear the insulation off the wires as the turret spun.

We have now managed the turret wiring to be as efficient as possible in terms of removal if a turret component breaks during a competition, using power poles to connect the turret wires to the rest of the robot circuit. We have designed a flat, nearly frictionless plate that we have installed under the turret plate to keep imperfections in the metal from tearing away at the wire loom encasing our turret’s wires. However, the energy chain leading to the turret components still does not follow a desired path. We are currently designing a guiding rail on the edge of the turret to corral the collection of wire into the plate that is meant to house it. We have mounted a motor on the slap-down intake, meaning that we had to wire the motor with its own motion in mind. CANcoder magnet shafts were remade to correct, finally allowing our encoders to get communications.

Programming/Scouting:

Our software team has been hard at work both on programming the robot and updating our scouting systems!

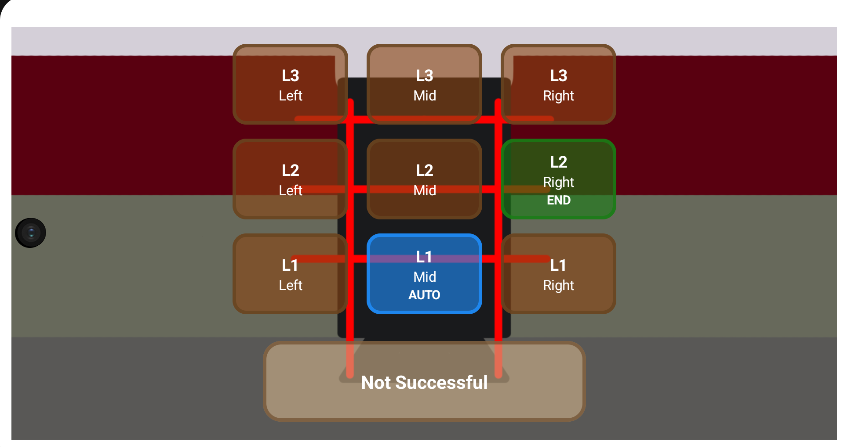

Robot/Touchboard Code:

For the REBUILT Season, our driver station will use a touchboard for quick commands.

Here is our 2026 DevTouchboard, and as always, credit to Team 2183 Tigerbot for the underlying NT4 and base 2025 branch that we worked from. On the frontend, we added the 2026 blue field SVG and refreshed the UI styling, including clearer connection-state indicators so drivers can immediately see when the robot is disconnected, connecting, or fully connected.

The autoBuilder.js file was heavily refactored to introduce structured start poses, updated field and robot constants, and a smoother path-planning workflow, along with FULL plan saving and loading.

On the robot side, we finalized the dynamic auto pipeline by integrating Touchboard plan parsing directly into Robot.java, generating trajectories from the JSON plan, resetting odometry from the selected start pose, and regenerating only when the plan or alliance changes. We also added supporting utilities, such as allowing the robot to know WHEN in the auto it is, so it can make decisions from our Touchboard strategy.

We’ve also created a method that allows the driver to press a button while driving, which automatically “picks up” their velocity vector, pays attention to the navgrid for the field, and goes through the closest trench. This allows our driver not to need to slow down for going through trenches, as they can trust that it will “correct” any misinputs.

We’ve also created our own AI model for Coral, trained first on Yolo26n, then converted to CoreML’s MLPackage for use on our Mac Mini. We have a ThriftyCam camera (which DO HAVE COLOR BY THE WAY!) on our intake, and it will allow us to auto intake for autos and teleop, as seen in the first video in sim.

Our robot-code this year is much simpler than last year's. Based on our Consul framework with extremely minor tweaks, it’s been super simple, to the point where we were programming a subsystem while deploying the other with an older version of code, and finishing BETWEEN deploys for testing. Consul framework FTW!

Scouting App:

Our scouters are currently refactoring code for the REBUILT scouting app, and wanted to give a quick preview of their work! We will eventually publicly release our app and event panel when they are finished.

Rather than releasing our app to the Play Store, we simply use 12 tablets from our school and download APK files onto them using Android Studio. Our scouters are interested in how other teams design their app flow. Here is our hang logic. Our app consists of 3 primary pages for Auto, Tele, and Endgame. We hold off the Auto hang and will have our scouters place the hang position at the end.

Impact

We're proud to announce that we've submitted our impact essay and executive summary… a solid day early to get it off our backs. Some points of pride that we'd love to highlight this year are our youth programs, our 3D Printer grant for elementary schools, and our continued work on our Mission to Engineer program. We focused on these a lot in our submission this year, and we hope that we've properly highlighted our passion for every aspect of our community outreach in our submission this year. All we have left to do for the submission this year is our impact video and prepare for the presentation! We hope to share a lot more of our documentation on our outreach events here in our open alliance, since it's such a core part of everything we do. We look forward to presenting our impact in Indiana, and hopefully even further, as well as learning what our fellow Indiana teams have been doing to impact their community this year!

A Sneak Peek at Team 328!

Team 135, the Black Knights, is Penn High School’s upperclassman FRC team. Since 1997, Penn’s FRC program has primarily been for upperclassmen, while underclassmen participated in FTC programs.

That changed in 2023 with the arrival of Team 328, the Golden Rooks, a sister FRC team built specifically for freshmen and sophomores. The goal is to give these younger students the chance to lead, try their ideas, make mistakes, and learn in a full FRC environment. By the time they move up to Team 135, they can bring their experience that helps strengthen the whole program. We also note that Team 328 is not a “Junior Varsity” team.

Right now, Team 328 is focused on their shooter. Here’s a quick sneak peek from testing.

The Golden Rooks are testing their robot

Go Black Knights!